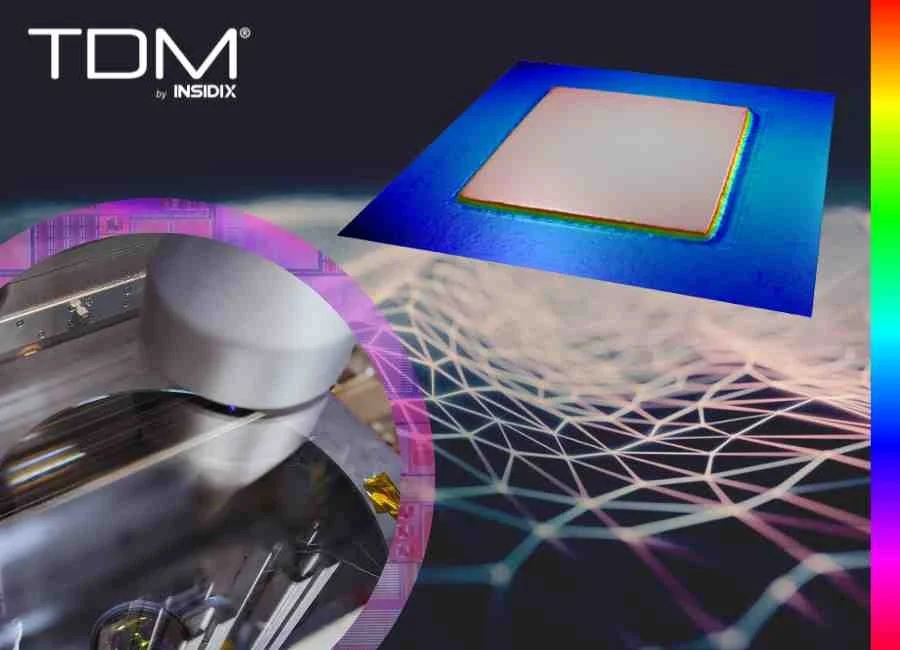

TDM

Topography Deformation Measurement

Assessing, simulating, and predicting the behavior of complex devices under thermal stress

Improve your measurement accuracy and reliability with TDM by Insidix's advanced warpage measurement system. Our cutting-edge technology utilizes phase shifting Projection Moiré, advanced 3D sensors, and temperature chambers that can endure extreme temperatures ranging from -65°C to 400°C.

Our state-of-the-art system is perfect for various industries including semiconductor, medical, automotive, aerospace, and electronics. So, whether you need to conduct research and development, quality and reliability testing, process development, or failure analysis studies, our system is the ideal solution for your needs.

TDM Characteristics

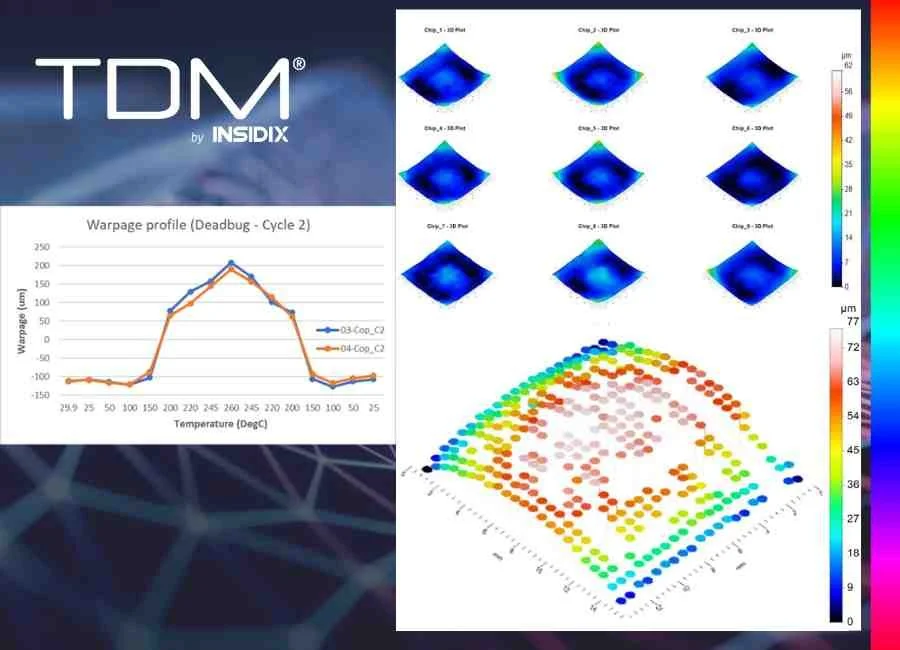

TDM's thermal warpage measurement equipment is a testament to its strength and cutting-edge technology. It offers precise, state-of-the-art solutions for measuring and understanding thermal warpage in materials and components.

<1 µm Accuracy

-65°C to 400°C Temperature Range

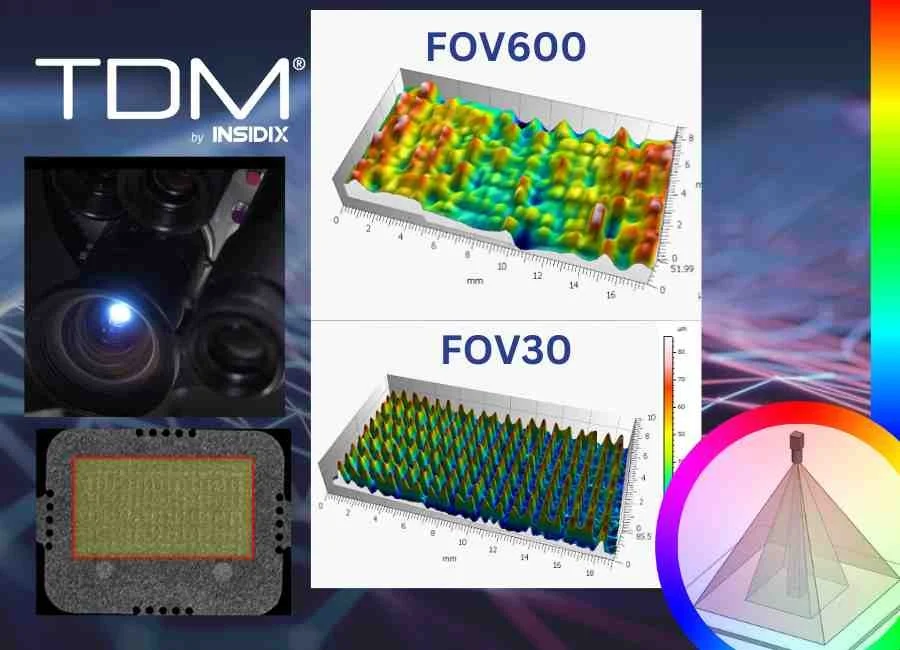

Patented Scanning + Multi-Scale Imaging

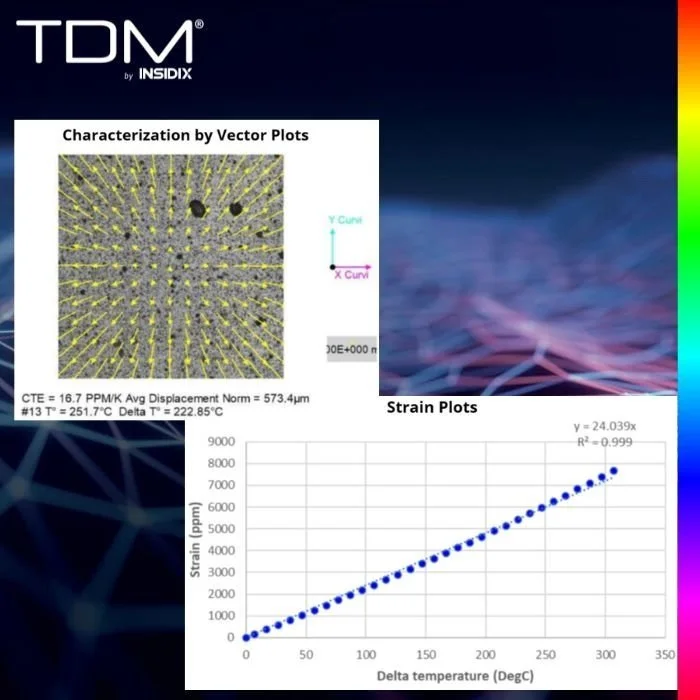

CTE + Strain Measurements

Application Studies

The TDM equipment offers versatile capabilities, allowing us to tackle a wide range of semiconductor applications. Our systems deliver exceptional results in application studies, demonstrating the robustness and reliability of our technology.

TDM Systems

Our Technology

Phase Shifting Projection Moiré

High Precision Imaging: Phase shifting Projection Moiré technology offers exceptionally high precision in imaging by utilizing phase-shifting techniques. This allows for detailed and accurate measurements in surface profilometry and deformation analysis applications.

Non-contact Measurement: It is a non-contact measurement capability. The technology can be used to measure objects without physically touching them, reducing the risk of damage or alteration to delicate surfaces.

3D Surface Profiling: TDM technology excels in creating detailed 3D surface profiles. Projecting a series of fringe patterns onto an object and analyzing the resulting moiré patterns can generate comprehensive 3D surface maps, making it valuable for quality control and product development.

Versatility Across Materials: Phase shifting Projection Moiré technology is versatile and applies to a wide range of materials. Making it suitable for diverse industries, from manufacturing to biomedical research.

High-Speed Measurement: TDM phase shifting Projection Moiré is capable of high-speed measurement, making it suitable for applications where rapid data acquisition is crucial.

IR Thermal Chamber

Wide Temperature Range: Experience exceptional versatility with our thermal chambers, offering an extensive temperature range from -65°C to 400°C, providing optimal conditions for various applications.

Uniform Temperature Distribution: Benefit from high homogeneity and thermal stability, ensuring consistent and reliable results across your samples. Our thermal chambers maintain a precise and even temperature environment for accurate testing and experimentation.

Versatile Sample Size Compatibility: Accommodate a wide range of sample sizes, from as small as 0.5 x 0.5 mm to as large as 600 x 800 mm. Our chamber designs will meet the needs of various industries, allowing flexibility in the size and type of samples you can analyze.

Swift Temperature Transitions: Boost your efficiency with rapid ramp rates up to 6°C per second. Our thermal chambers are equipped with advanced technology to facilitate quick temperature changes, saving you valuable time during testing and experimentation.

Dependable IR Technology: Rely on the stability and precision provided by our thermal chambers, which incorporate reliable infrared (IR) technology. Ensuring accurate temperature control and monitoring, plus enhancing your thermal testing processes overall performance and reliability.